Wastewater treatment for food processing plant, and case Studies

Food processing industries include alcohol and beer manufacturing plants, as well as food processing plants such as vegetable processing and seafood processing.

In particular, wastewater from food processing is characterized by high BOD levels of carbohydrates, fats, and proteins.

In addition, the quantity and quality of wastewater fluctuates greatly with time and season, and it is prone to spoilage, those characteristics affect treatment.

【Fooding center】

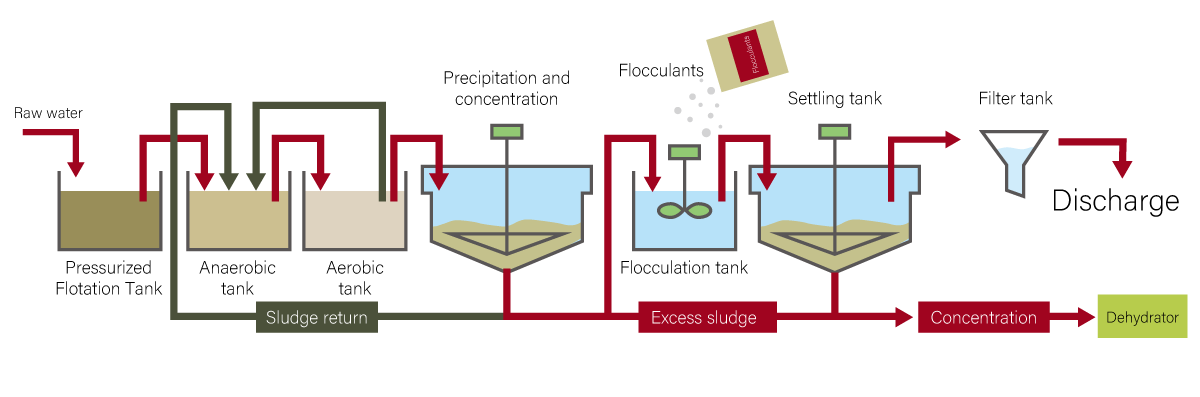

Kitchen wastewater from fooding centers and restaurants has a high pollution load of organic matter and fats and oils, so there are technical points to maintain the balance of pressurized flotation and activated sludge.

It is important how to properly treat vegetable oils and other fats and oils for treatment efficiency and hygiene control.

【Alcohol plant and brewery】

Alcohol plants that produce alcohol through fermentation or distillation processes produce concentrated distillation effluent.

The effluent is acidic wastewater with very high BOD and suspended solids.

In the case of beer breweries, the wastewater includes water from compression washing and malt waste.

A sugar plant that refines brown sugar and a seafood processing plant that manufactures canned goods and sausages each require their own unique wastewater treatment technology.

Wastewater treatment methods for food processing plant, etc.

There are various combinations of pressure floaters, dehydrators, activated sludge treatment equipment, etc., depending on the type and conditions of the wastewater, therefore it is necessary to select the most appropriate chemicals for each treatment facility.

Traditionally, sludge generated from wastewater treatment was dried and incinerated, landfilled, composted, converted to animal feed, or converted to methane gas, however in recent years, efforts have been made to recycle it and various technologies have been developed.

In general, fats and oils are separated by pressurized flotation or using chemicals such as polymer flocculants.

Separated fats and oils become excess sludge, which is difficult to dewater, therefore it is necessary to select an effective dehydrator and flocculant brand.